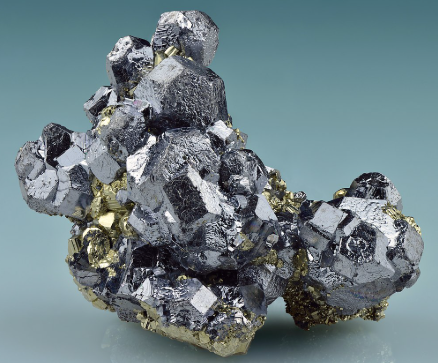

1、Lead Ore

Lead-bearing ores in nature, whose main chemical element is lead, commonly include galena (PbS), cerussite (PbCO₃), and lead sulfate (PbSO₄). They are often closely associated with sphalerite (ZnS) and pyrite (FeS₂), and are also found alongside various valuable elements such as silver, copper, bismuth, antimony, and gold. They are the initial raw material for the lead industry, and through mining and beneficiation processes, they provide the foundation for subsequent lead extraction and smelting.

2、Lead Concentrate

Lead ore, after being crushed, ground, and enriched through beneficiation (mainly flotation), yields a product with significantly improved lead grade. The main mineral is galena, and it is also rich in valuable metals such as silver, zinc, and copper. It is the core raw material for lead smelting, primarily produced through pyrometallurgical processes such as sintering-blast furnace or direct smelting. Its comprehensive recovery value depends particularly on the extraction of associated silver.

3. Lead alloy:

Lead alloys are alloy materials made primarily of lead, with the addition of elements such as antimony, tin, calcium, and arsenic. Examples include lead-antimony alloys and lead-calcium alloys. They are characterized by high density, corrosion resistance, good ductility, or adjustable hardness. They are produced through smelting and formulation and are widely used in fields such as battery grids, radiation protection, solders, and mechanical counterweights.

4. Lead ingots:

Lead ingots are a primary form of metal obtained from lead concentrate or recycled lead through sintering and reduction smelting. Their purity is typically 99.5% to 99.99%, containing trace amounts of copper, silver, bismuth, and other impurities. It is the main commercial form of lead smelting and can be directly used in battery manufacturing, alloy formulation, chemical raw materials, and the production of radiation shielding materials.

5. Electrolytic lead:

Electrolytic lead is a high-purity lead product obtained through electrolytic refining from crude lead or lead anodes. Its purity is generally not less than 99.99%, and it exhibits uniform and dense crystallization. It has extremely low impurity content, excellent chemical stability and radiation shielding performance, and represents the highest purity form of lead. It is primarily used in specific fields such as nuclear industry protection, high-end batteries, ultrapure reagents, and precision electronic devices.

6. Lead waste:

Lead waste refers to lead-containing scrap metal or industrial residues, mainly from lead-acid batteries, lead alloys, lead pipes, and protective materials, with varying lead content. As an important recycled lead resource, its recycling and smelting can significantly reduce the consumption of primary lead ore and environmental pollution, and is a core component of the sustainable utilization of lead resources.